Introduction

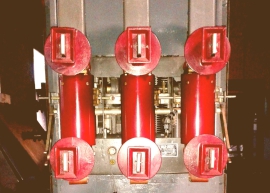

These types of the disconnectors are used in the normal height of the bus to transfer the current to the other equipments in the bay and will function as a no load switch. This will be installed in incoming and outgoing sides of the distribution equipment according to the substation bay requirement. This will be operated in conjunction with the Circuit breaker for any switching on / off and maintenance purpose.

Earthing switches shall be provided in the disconnectors based on the requirement and for earthing purposes. The earthing switches will be closed when the disconnector is in off condition and vice versa for earthing the induced current and voltages on the busbar when the circuit is open condition / maintenance purpose. This also will take care of the short circuit current when the main disconnector is in open condition.

CENTRE BREAK DISCONNECTOR COMPRISES

The Hamper assembly consists of two moving arms called the male and female arms, each mounted on the top of the rotating support insulators. The arms are made out of tubular or channel sections of Aluminium alloy depending on the current and voltage ratings of the disconnectors. The male copper contact and female copper contact fingers are silver plated and mounted onto the arms.

The male and female hamper assemblies are connected to the terminal stem by using either flexible copper strips or copper fingers for the safe transfer of current from the moving arm to the fixed terminal stem of the disconnector.

The contact between the male and female contact is a line contact and the contacts provided are of the reverse loop type. Each contact finger is provided with a contact spring which, ensures that the required pressure is maintained.

The terminal stem onto which the terminal connector is fixed is made of aluminium alloy for 420kV disconnectors up to 2500 Amps & 245kV Disconnectors of 2500 Amps; and of copper for all 245kV and below Disconnectors up to 2000A. For 3150Amps rated disconnectors, only Copper terminal stems are used. Where copper terminals are provided with tin plated for connection to aluminium alloy terminal connectors. Contact corona rings are provided at the male and female hampers wherever necessary.

In the case of the centre break disconnectors the support insulators are used to support metallic hampers of the disconnectors and to rotate through 90 degrees to open and close the disconnectors, to provide necessary insulation between live parts and ground. Insulator corona rings are provided on the insulators wherever necessary.

Disconnector base is made out of mild steel welded assembly. The base consists of two flanges at either ends for mounting the support insulators. These flanges are provided with the necessary holes at the required pitch circle diameter to match the holes provided on the base flange of the insulator. The flanges are welded on the bearing shaft and are assembled with two numbers of bearings, in a bearing housing. These bearings are seated one on the top and another one on the bottom of the base assembly and these ensure free and smooth movement of disconnector arms. Bearing covers are provided to ensure that water and dust do not enter the bearings. Provision is made at the two ends of the bases to mount earth switches if required. Provision is also made on the base for mounting the mechanical constructional interlock between disconnector and earth switch wherever required.

The base is provided with mounting arrangement at two points for fixing the disconnector base with the supporting structure.

Earthing pad / earthing studs are provided at two points at the extreme ends of the base for connecting to the customers sub station earthing system.

Inter stack coupling pipes are provided to couple the two columns on the same phase of disconnector so as to ensure simultaneous rotation of the two poles columns driven by the common operating mechanism. The coupling pipes are linked to the base flange on which the insulator is mounted by metallic pin to ensure easy assembly / dismantling at site. Normally the inter pole coupling pipes are assembled on to the base and set at factory prior to despatch from works.

Inter Phase coupling pipes are provided to couple the three phases of the Disconnector and operate all the three phases from a common operating mechanism in the case of Mechanically Ganged three pole Disconnectors. These are not required in the case of single pole Disconnectors where each pole is operated by its own operating mechanism. The coupling pipes are linked to one base flange on each phase of the three pole disconnector. These are dispatched as loose items and are to be assembled at site. Provision is available to do minor adjustments in length of the coupling pipe to suit site conditions.

Wherever specified, support structure of tubular types for 420kV disconnector and lattice type for 245kV and below disconnectors with necessary foundation bolts can be supplied. Plates are welded on to this tubular support structure fabricated out of welded sheet steel for 420kV Disconnectors for mounting the operating mechanism boxes. The height of this support structure can be varied to accommodate the bus height as required by the purchaser’s layout and system.

The operating mechanisms of the disconnectors / earth switches are mounted on to the structure on plates provided, being bolted with the angles that are provided on the mechanism box. Motor Operating mechanism or manual Operating Mechanisms can be supplied as per customer requirement.

The following interlocks are provided for the Horizontal centre break disconnectors.

- A Mechanical constructional interlock between the disconnector and earth switch has been provided to ensure that the Earth Switch can be closed only when the Disconnector is in the open position and vive versa.

- An electrical (Bolt coil type) interlock has been provided in each motor operating mechanism for interlocking between manual and motor operation of Disconnector/Earth switch. This ensures that the motor circuit is cut off when the manual operation is under progress.

Optionally electro-mechanical (Castel key type) interlock can also be provided. In some cases, only electrical bolt coils are provided as interlocks solely controlled by electrical circuits.

In some cases, only electrical bolt coils are provided as interlocks solely controlled by electrical circuits.

Based on customer needs either Electro mechanical or Electrical interlocks will be provided.

Electrical contact is provided in the Electrical circuit of the Motor Operating Mechanism for the Purchaser to wire-in the external interlocks if any to ensue that the Disconnectors/Earth switch can be operated only if all the interlocking conditions are satisfied.

NOTE:

- Horizontal Centre Break Disconnector can be supplied by us either without Earth switch, with Single Earth switch or with Double Earth switch.

- Centre Break Disconnectors are normally offered for horizontal, normal level, upright mounting. But on request these can be offered for other types of mounting like series, vertical, higher level, under hung, tandem etc.,

- Horizontal Centre Break disconnectors / Earth switches supplied by us are generally Mechanically Ganged for operation of all three poles from a common operating mechanism cabinet. However we can supply 420kV Centre Break Disconnectors with the three poles being operated by 3 separate mechanisms, which are electrically ganged to operate together, if so desired by the purchaser.

- Horizontal Centre Break disconnectors / Earth switches supplied by us are generally Mechanically Ganged for operation of all three poles from a common operating mechanism cabinet. However we can supply 420kV Centre Break Disconnectors with the three poles being operated by 3 separate mechanisms, which are electrically ganged to operate together, if so desired by the purchaser.

- Horizontal centre break disconnectors can be

supplied with the following ratings (included in our present range of manufacture).

Maximum Voltage 420 kV Maximum current 4000 Amps Maximum short time withstand current 50kA r.m.s for 1 Sec with 125kA peak (or) 40kA r.m.s for 3 sec with 100kA peak. - unless specifically stated in our offer, all cabling and wiring external to our operating Mechanism cabinets are excluded from the scope of our offer.