Introduction

We are the leading manufacturer of high voltage Disconnecting switches from 11kV –550kV Level. Centre of excellence for Design and Manufacture of Centre break , Double Break and Pantograph Dis-connectors

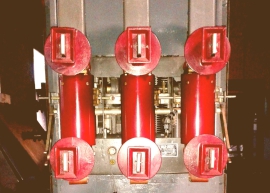

CENTRE BREAK DISCONNECTOR COMPRISES

Our range of motor driving mechanisms is designed to ensure the best performance, with reliability resulting from our 40-year experience.

Over 50,000 disconnecting switches installed in many countries worldwide give the guarantee of a best-buy.

S&S power uses only the highest quality corrosion-resistance materials.Our gear are lubricated for life and therefore do not and maintenance or greasing.

The main worm-gear assembly, which provides operating torque and supports the weight of the mechanism, is bolted to the supporting structure allowing the housing to serve only as a weather proof covering. Air vents, an internal heater to Prevent condensation and ensure trouble-free operation.

The electrical operation of the disconnector through the drive mechanism can be done remotely, or from local push buttons. A local/remote selector prevents any Interference between the two control modes. The manual operation of the disconnector is possible by the means of a manual handle.

A manual operating handle is stored just inside the operating mechanism. The insertion of the handle is allowed only if the electrical interlocks are permissive and the pushbutton is energized and operated. The action also switches off automatically the motor supply, to prevent any accidental electrical operation.

Depending on the request the actuation of the integrated earthing switch can be done manually by an operating rod or a handle or electrically as well. The operating force (manual or motor) is transmitted by an irreversible reduction gear, which prevents the disconnector from changing position due to various environmental (wind, seismic,..) or electro dynamic stress. The motor is always fed through an MCB.

Various combinations of worm-gear ratios give a wide range of output torque and operating times. As a result, S&S mechanisms are suitable for most disconnectors and earthing switches, even those of other manufacturers. Motor and manual mechanisms are fully inter-changeable, allowing the motorization of disconnectors originally installed with manual mechanisms.

Upon request, the mechanism can be equipped with the following accessories: Operations counter, internal lamps, Sockets, Key interlocks, additional auxiliary switches, key-lock for housing door, pad lockable end position, signaling lamps, additional limit switches, earthing strips.

S&S designs, manufactures, tests and delivers its disconnectors in accordance with the latest IEC and ANSI standards.

Our disconnector manufacturing site certified according to the ISO 9001:2015 Quality Management System.

- The housing is made of aluminium alloy to prevent corrosion and guarantees a high protection degree up to IP 55 upon request.

- An anti-condensation heater prevents harmful moisture condensation inside the cabinet.

- The external components are either made of aluminium alloy or hot dip galvanized or stainless steel.

- Mechanical endurance tests at up to 10,000 close/open operations have been proven the reliability of all mechanical parts.

- Fully operational from -50°C to +55°C, S&S mechanisms have confirmed their performance in the various climates of India, UK, Africa and Vietnam.

Depending on the model the drive mechanism includes 1 or 2 motors(3-phase AC or DC) and gear boxes providing a high torque, exceeding that required by the disconnector. This ensures a high safety factor to guarantee proper operation, whatever the site conditions are.

It can operate the three poles of a disconnector through driving shafts and rods or with one drive per pole: one master and two slave units. The motor limit switches are also adjustable in same way. These adjustments possibilities ensure that, in any conditions, the position signaling reflects exactly the position of the main contacts.

TYPES OF OPERATING MECHANISMS

Various types of operating mechanism are available; varying with the customer requirements.

- Manual Operating Mechanism (MOM)

- Motor Geared Mechanism (MGB)

- Manual Geared Mechanism (MOM)

- Combination of MGB / MOM

- Combination of MGB / MGB

S&S providing the various kinds of enclosures:

- Aluminum enclosure

- Stainless Steel enclosure

- MS power coating enclosure

Disconnectors can be equipped with Manual or Motor drive Mechanisms depending upon the site condition and customer requirement. The Motor of drive mechanism can be D.C operated or A.C operated. The selection of auxiliary switch and Limit switch contacts depends on the customer requirement. The range of motor and over load relay selection depends on the voltage rating of the Disconnector. The direction of rotation available for both LH and RH sides as per requirement.

Technical data

| MGB/MOM | MGB | MOM(G) | MOM | |

| Combinations | Combined | Individual | Individual | Individual |

| Rated torque | 800 Nm | |||

| Disconnector switch | Motor | Motor | Manual (Geared) | Only 33kV |

| Earthing Switch | Manual | Motor | Manual (Geared) | Manual |

| Weight | ||||

| Operating angle | 90-180 Deg | |||

| Operating time (motor) | 20s | |||

| Motor *rated Power *rated voltage (+10%-15%) *frequency | < 600W110-220 Vdc415 Vac 3Ph50 Hz | |||

| Anticondensation heater

|

80W110-240 V | |||

| Auxiliary switches

|

|

|||